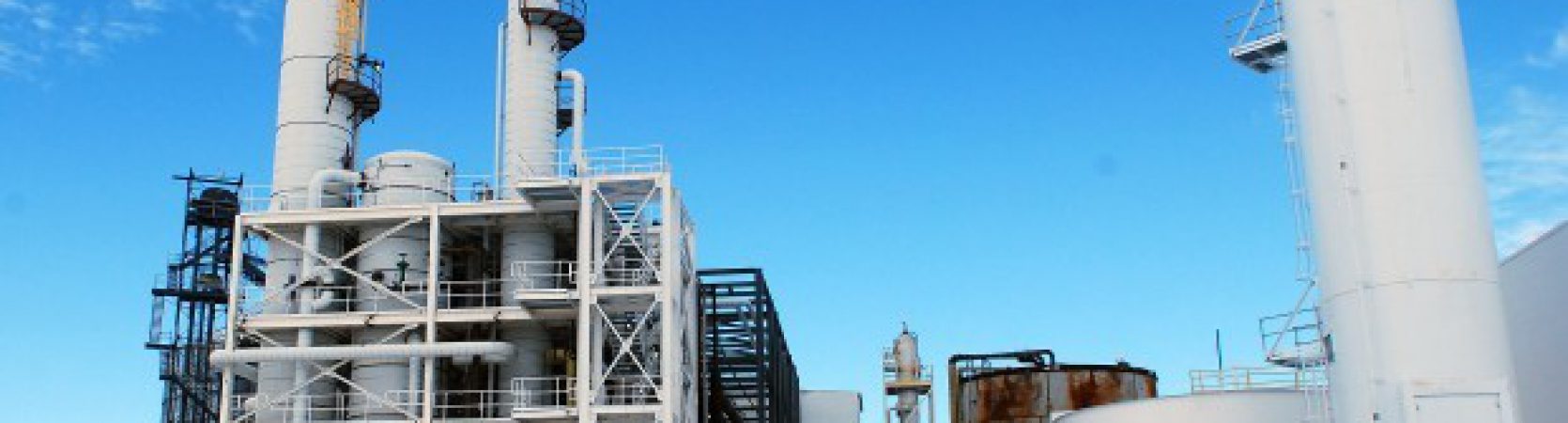

A renewable fuel producer was the first commercial plant to make ethanol with virtually no fossil fuels for heat, using manure to make biogas instead. It owns and operates a 22-mill-gallon-per-year ethanol plant located in Mead, Nebraska.

E3 commissioned EAD to identify the facility’s design and installation issues to correct bugs prior to startup. Throughout the plant, 800 I/O points needed to be commissioned, as well as control systems for digesters, grain handling, ammonia purification, the ethanol plant proper and utilities not yet integrated.

EAD developed the entire automated controls installation punch list and managed the correction of each issue. We identified, designed and installed control systems that were left out of the original scope of work. The team worked extensively on the I/O checkout, instrumentation set-up, calibration and verification of the control systems throughout the plant.

EAD also partnered with another third-party vendor on the DCS configuration and integration, while they designed the controls for the hammer mill area and fabricated the heat trace and fire water control panels. EAD personnel were present during commissioning and startup.

Services:

Automation

Project Management