A Fortune 500 global leader in biotechnology research and development and enzyme production contracted with EAD to design and install an automated process waste system that could replace their existing manual system. Our client’s bio-fermentation facility’s enzyme production process involved growing bacteria and then filtering out the bacterial body waste through clay-packed filters. Facility staff was required to manually add lime to the mixture to sterilize and denature the bacteria. Since lime is a respiratory irritant and the enzymes are allergen-producing, facility personnel were required to wear respirators throughout the facility.

EAD employed our process engineering expertise to create a conceptual design for a new, more efficient, and safer production process that automated the bacteria denaturing process. The project took multiple years with many complex phases. Each phase required a design review, construction cost estimates of increasing accuracy, and re-scoping for the next phase. We were able to take this design from concept to project completion.

EAD’s solution involved using heat, rather than lime, as the denaturing agent in the enzyme production process. Our design called for the addition of steam-contact paddle mixers. The steam-contact paddle mixers ensured that the microbial biomass could be completely removed from the waste stream. The new design eliminated the need for facility personnel to manually scoop lime. Eliminating manual processes allowed them to focus on other production tasks. EAD also isolated and enclosed the production equipment within a smaller physical space, so that plant personnel had more room to work safely without the need to wear respirators.

In-House Expertise

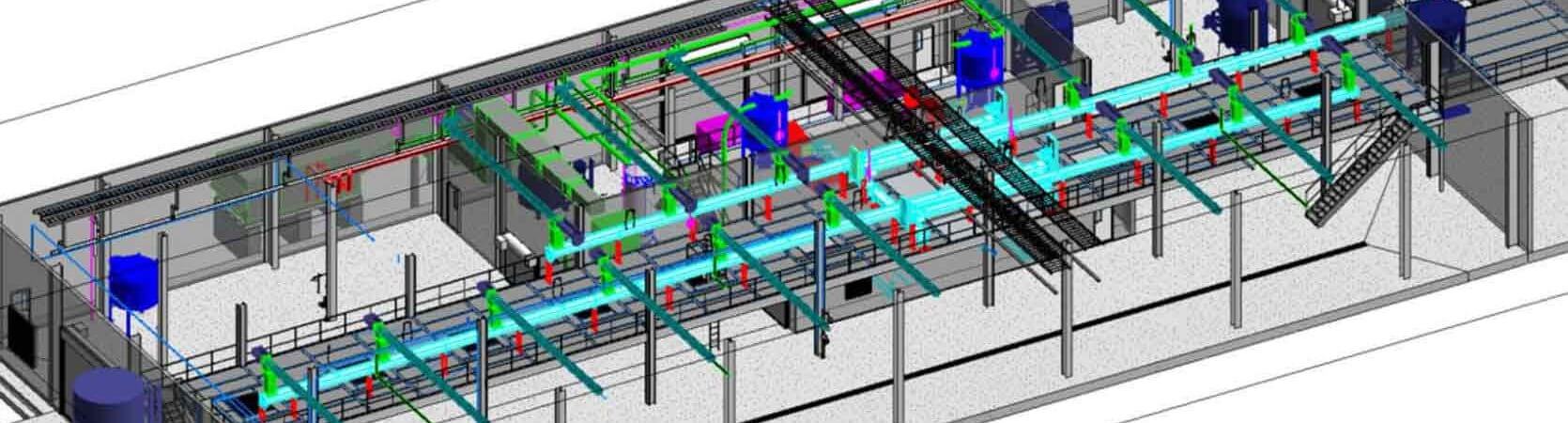

So that our client could better visualize our proposed design, our in-house design team developed a model of our client’s existing building in BIM and 3D CAD. We added our proposed modifications within this model, providing details on everything from the process equipment, piping, HVAC units, and electrical equipment to the cable tray and new interior structures. By project close, our client not only had a complete virtual model of their redesigned building for their future use but a safer and more cost-efficient production process.

To learn more about the cool projects EAD has done and continues to do, visit our Project Profile page.

Client: Fortune 500 Biotech Leader

Location: Nebraska

Market(s) Served: Pharmaceutical, Biotech R&D

Services

- Project Management

- Engineering

- Safety Hazard Mitigation

- Technical Drafting