A client of EAD’s experienced an unfortunate incident in an overseas facility involving a mobile process vessel. A wheeled vessel was being transported through the plant, as is commonly done. During transport, the vessel tipped over and seriously injured the operator. To their great credit, this client initiated a corporate-wide effort to identify any other mobile vessels that could be a risk. The result was a unique project aimed at preventing another such injury.

A client of EAD’s experienced an unfortunate incident in an overseas facility involving a mobile process vessel. A wheeled vessel was being transported through the plant, as is commonly done. During transport, the vessel tipped over and seriously injured the operator. To their great credit, this client initiated a corporate-wide effort to identify any other mobile vessels that could be a risk. The result was a unique project aimed at preventing another such injury.

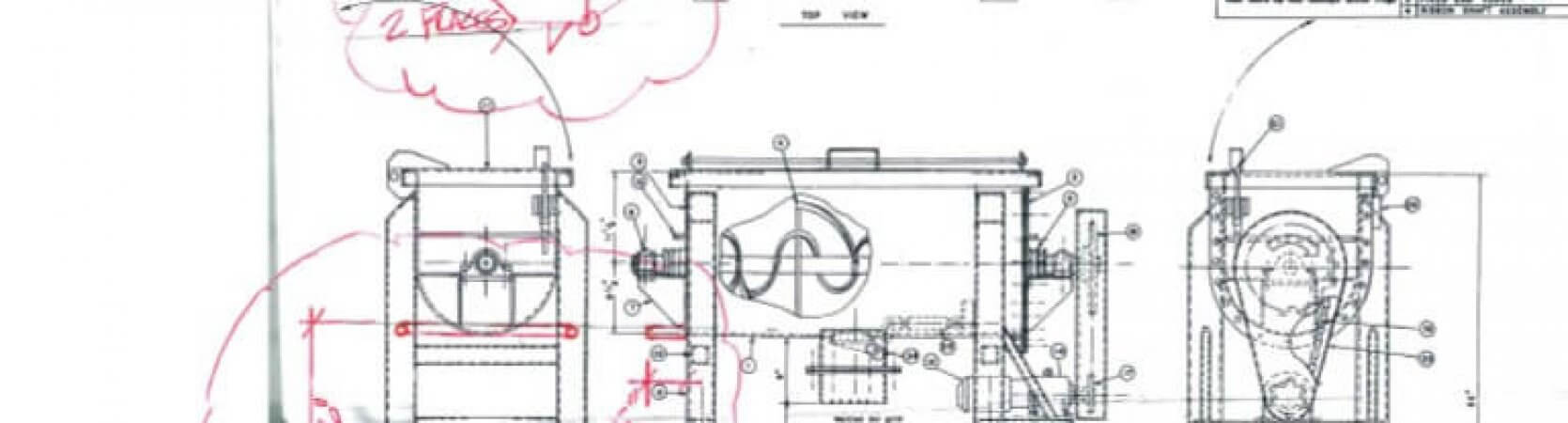

EAD’s engineers were assigned the task of evaluating the tipping stability of various wheeled vessels for one of their facilities. The stability analysis included determining force required to start or stop a vessel from rolling, calculating momentum and sloshing effects of stopping a filled vessel, and other possible dynamic concerns.

As a result of the evaluation, corrective modifications were recommended for a small number of vessels. Some vessels were recommended to have a push bar installed near the center of mass so the operator is less likely to use a tank top nozzle to pull the vessel and cause it to topple. Other vessels were recommended to have vertical stops welded to the vessel frame to prevent the vessel from overturning completely if it became unstable. Engineered drawings showing optimum dimensions and locations of vessel modifications were developed by EAD.

Although this was not a highly visible project and did nothing to improve production throughput or energy efficiency, the client valued EAD’s willingness and flexibility to partner with them to address a concern of great importance – keeping their teammates safe.