What is Kanban?

When translated from Japanese to English, Kanban means “billboard,” which may not invoke images of a powerful project management tool. While Kanban is just one idea, it has multiple applications. Kanban is used in inventory control systems, project management, and continuous improvement initiatives of all sizes. First popularized in the automotive industry, it has been adopted to more than manufacturing.

Kanban is an evolutionary approach to system and process change in operations. Kanban is also a tool to discover workflow problems and derive more consistency in products and services. There are four primary principals of Kanban:

- Visualize Work

- Limit Work in Process

- Focus on Flow

- Continuous Improvement

How To Use It

Defining Kanban

Defining Kanban this way still leaves us more of an ideology than a tool. Two of the most common Kanban tools are used in inventory management systems and project management. As part of EAD’s Proven Process for providing professional services, we use a Kanban board to visualize our project management. It is a way to coordinate and organize obstacles of delivery teams by setting clear priorities and initializing focus.

Visualize

The power of visualization is what makes a Kanban board so useful. Neuroscientists claim that about 90% of the information that our brain processes are visual. Of the visual information that our brain processes, pictures and color coordination are among the most effective ways of disseminating information. These concepts are how Kanban boards create value for EAD’s project teams.

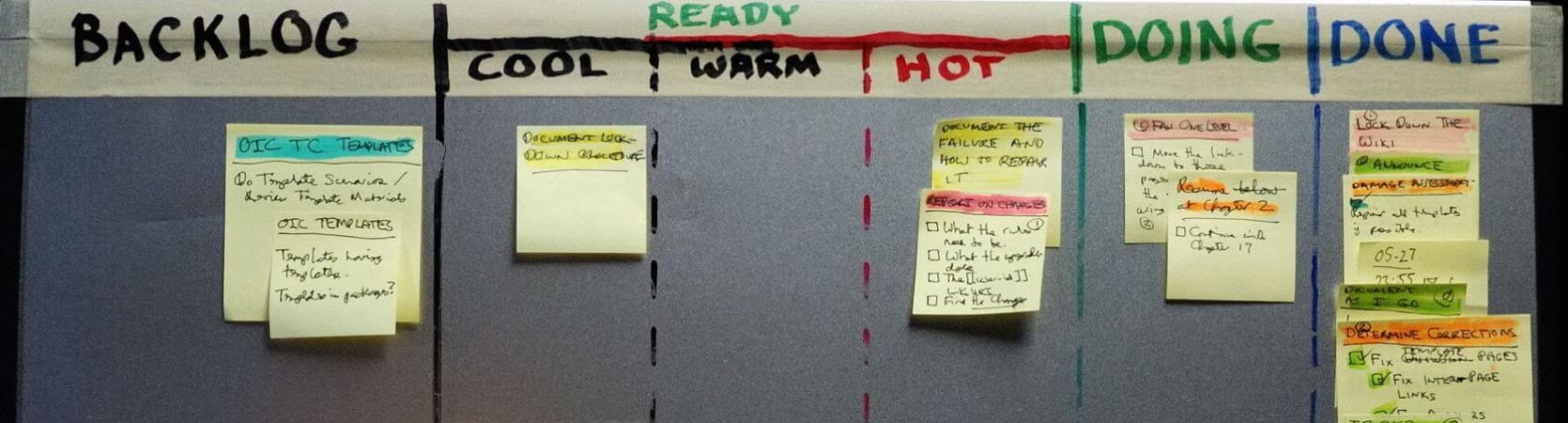

Let us visualize an example of a simple, physical Kanban board. A basic Kanban board has three sections: To Do, Doing, Done. As a project is broken down into tasks, everything starts in the “To Do” section, and moves to “Doing” while it is being worked on, and “Done” when the task is completed. Tasks are commonly represented by sticky notes or note cards on a pushpin board. To give a Kanban even more effective functionality, consider switching to a digital Kanban board.

Each task may have several subtasks associated with the completion of the more significant task. These are often represented by cards of similar colors to make it even more visual. Generally, a task is broken down into several colored cards with a subtask number associated to the main task. This shows the sequence of how sub-tasks need to be completed. These subtask notes include information such as the details of the project, who is working on the project, the importance or sequence, the date it must be completed, and other general information. With the documentation of this information, we do post-project lessons learned analysis to improve project management.

Adaptability

This three-section Kanban is just a simple example of a Kanban board. Nearly everything mentioned above could be adapted to fit better how one wants to manage their projects. For example, the color of the card could be associated with the engineering discipline or a physical area of the project. There could be several other vertical bin sections of the board, such as a quality review, or to represent different stages of the doing section. We could add rows, numbering systems, give a different meaning to the shape of cards, or orient the cards in different ways. The possibilities are endless in creating the communication system of the board. The Kanban board is a tool of visualization that is customizable to the problems that we are faced with.

Summing It Up

There are many ways to structure a Kanban board, but the idea remains the same. Make sure that you have somewhere you can visually represent and track the progress of a project. Use the board to anticipate and react to problems, consolidate your work in process to increase flow, and document lessons learned. Finally, at the end of the project, a team would have the opportunity to review how the project went and has plenty of information to use for the analysis. All of this will produce value for the users. Such a simple visualization tool has made a large impact on what we have been able to accomplish.