What is Lockout / Tagout?

Importance: Used to remove the risk of hazards when working on equipment

1. Saves lives

2. Prevents damage to equipment

3. Allows for easier and safer maintenance

According to OSHA, around 10 percent of serious industrial accidents are a direct result of a failure to control hazardous energy. Standard 29 CFR 1910.147 puts the onus on the employer to provide the protective measures necessary to keep employees safe from such hazards.

Lockout Tagout (LOTO) procedures are developed to safeguard employees from the unexpected energization or startup of machinery and equipment or the release of hazardous energy during service or maintenance. Lockout/ Tagout processes are designed to ensure all energy sources are controlled before working on a piece of equipment or a line.

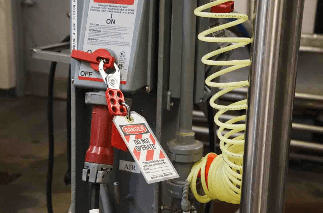

Lockout – Lockout is the first step in the process after shutdown. The final step ensures control over the energy source. This is the most crucial in controlling the energy source and preventing unplanned discharge.

Tagout – Tagout is an vital communication process for the LOTO procedures to remain safe. The tag identifies the owner of the lock and the reason for a lockout. The tagout helps inform and deter personnel from interfering with the equipment. Furthermore, these devices are the final safety net for the personnel performing the work.

Companies that utilize dangerous industrial equipment must have a formal Lockout/ Tagout program. For large facilities that house a variety of types of equipment with complex systems, the task of implementing a Lockout/ Tagout program can be daunting.

What does your lockout process look like?

Evaluation

Do you have a lockout system?

Documented Program

Do you have a written lockout program?

Documented Procedures

Do you have written procedures for all machinery?

Training

Do you conduct training for your lockout program?

Equipment

Do you have proper equipment for all your lockout procedures?

Access

Is the equipment and procedures available and accessible?

Audits

Do you perform regular inspections?

How do you implement your audits?

EAD integrates trained professionals directly into your facility to create a LOTO program customized for your facility.

OSHA mandates the writing of LOTO procedures specific to each piece of potentially hazardous equipment or process and the identification of all energy sources and energy isolation devices.

At EAD, we embed engineering professionals into your facility who are trained in all aspects of the LOTO program. EAD becomes integrated among your team, our professionals not only learn about your equipment but about your company processes and culture. We do this to ensure that your LOTO program integrates seamlessly with your other facility procedures.

We provide you with tailored training that fits your LOTO program

EAD can provide both authorized and affected employee training. Authorized employees are those who service the machinery and use the procedures that we implement. We also provide training to those that may not actually be authorized to use the equipment and systems but still need to be informed about the LOTO procedures. Our engineers work side-by-side with your staff to customize training that fits the needs of your facility.

Working with EAD will allow you a choice to select the right professional to fit for your facility/team. EAD only sends professionals who are experienced, meet our high safety standards, and support our core values. We understand that you may have select engineers with whom you would prefer to work. EAD provides you with the option to select among any of our highly qualified staff and to switch staff throughout the project.

Machinery includes various hazards to operators/engineers

- Electricity

- Extremely hot or cold surfaces, which may cause burns

- Gases – poisonous, suffocating, and explosive

- Gravity – falls from height, falling parts, or mechanisms that work with or against it

- Hydraulic pressure

- Liquids – gasoline or other fuels, chemicals, and water

- Moving parts – fans, belts, gears, saw blades, and presses

- Pneumatic pressure

- Radiation – intense visible light or thermal radiation, as well as ionizing radiation or charged particle beams

- Spring tension

- Steam

Q/A recap

Who uses Lockout Tagout (LOTO)?

LOTO is an OSHA 1910 commercial requirement. LOTO is an OSHA 1926 residential requirement. For additional information regarding Lock Out Tag Out, visit OSHA. https://www.osha.gov/SLTC/controlhazardousenergy/

Who should handle your LOTO process?

It’s important to note that workers are trained in the purpose and function of the energy control program. And have the knowledge and skills required for the safe application, usage, and removal of the energy control devices. Also, it’s a requirement to develop these plans as part of a MOC process if at a PSM regulated site. Some use it to train employees on the systems. Often operators make them, or some companies do it on a case-by-case basis and define a new lockout every time.

Our experts reside both onsite and offsite, including a third-party organization with a wealth of resources and experience in multi-discipline LOTO applications.

For additional information regarding EAD’s safety culture, please visit our safety culture page or give us a call at 402.884.8650. EAD will connect you with a LOTO expert to answer any questions you may have.