EAD can upgrade your obsolete PLCs on a tight schedule to make sure you are up and running before your scheduled start time.

EAD specializes in migrating obsolete PLC platforms like SLC and PLC-5 to Studio 5000. Utilizing a phased approach, our experts can perform migrations during tight downtime windows. We have developed a unique process to help you meet your goals.

We make a point to understand what is driving your upgrade project and what the challenges are. Management may be hard pressed to allow extra downtime on a line to complete a migration. They may think that because the PLC that is already there works, downtime is not needed.

We help to eliminate such downtime concerns by taking on schedules that other firms may not. EAD is often asked to fit migrations into tight windows of time. We trust that our process will leave us with minimal issues at startup and are committed to working according to our clients’ schedules, including nights, weekends, or twenty-four-hour days, if required.

Our goal is always to complete a control systems migration during a standard maintenance or cleaning downtime. For larger projects, this usually means that we must execute the project phases. A migration typically involves several steps: First, we convert the program and the processor, and then we test and turn the line over to our clients’ operations team. After the processor is programmed and tested, it is much easier to convert individual I/O racks as they fit into your schedule.

EAD has developed software that can automatically update the tags in your HMI or SCADA system. It can also replace all necessary I/O tags and descriptions in the program. These automated processes reduce time, cost, and the likelihood that an item will be missed.

Have you done a conversion and encountered strange analog values or discovered that the PIDs do not work correctly? Or maybe you’ve found that the program is just behaving in strange ways. These are issues we make sure to correct before our clients’ manufacturing lines go into production. Many of our clients migrate their systems using Rockwell’s conversion software. This tool is good, with an accuracy of about 90%. However, it can miss items, which can cause issues during the system start-up phase. In fact, is for this reason that our controls migration experts are often called in to help. They know what items the conversion tool misses and follow a system validation process that ensures the start-up phase will be error free.

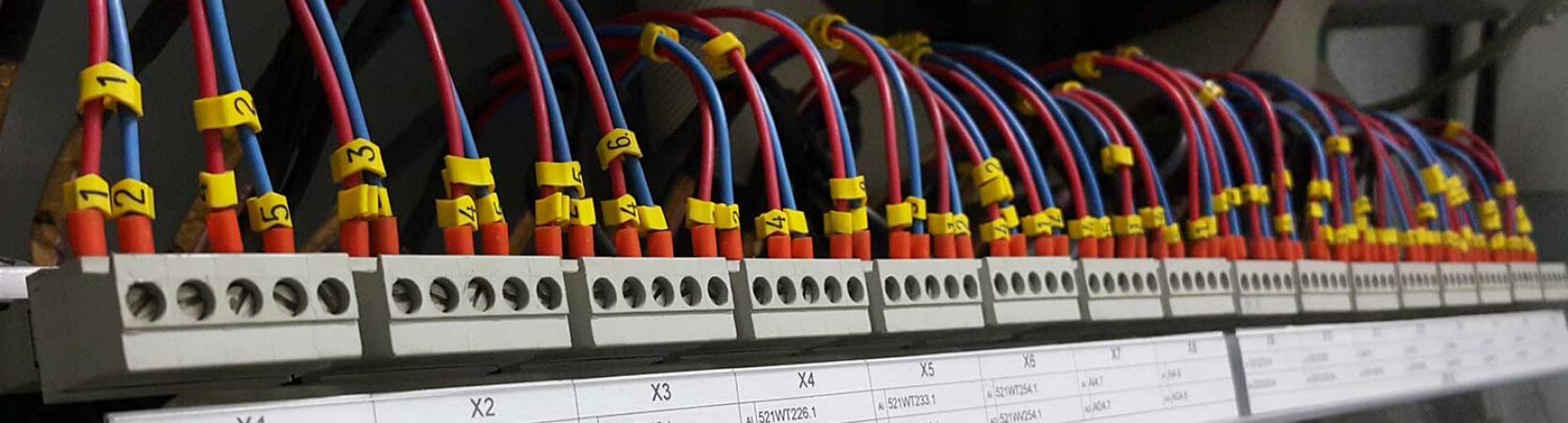

EAD is also able to design hardware that is tailored to the specific requirements of your facilities and systems. When our clients ask us to design new back panels, for example, we design with the exiting wiring in mind. This way, our clients need only to disconnect and reconnect their wiring without pulling any new wires. We may suggest replacing I/O racks and re-using the same back panel, or, when our clients have very tight windows of time, use adapter modules to plug the existing PLC-5 Swing Arms into new ControlLogix I/O cards. Ultimately, our goal is to ensure our clients get the right fit and understand the strengths and weaknesses of every available option.

EAD will also update your I/O schematics with the new tags and wiring changes. We can create a wire label list with both the new and old labels. Electricians use this information to update the panel and field tags so that it is easier for your maintenance staff to perform troubleshooting in the future.

Before going into production, we validate every change we have made by simulating from the HMI application through the PLC. We know that production time is critical, so this validation step is key to the success of the project. If we are only converting the processor and have one or more Remote I/O racks available, we will configure a test I/O rack and verify that each module in each rack is communicating with the new processor as it should. This step helps ensure a quick and easy start-up process.

Finally, we provide continued support of any upgrades or other work performed on your system and will stay with you until your line is performing as we said it would. We train your maintenance staff on any changes we have made to your system so that they can successfully support it in the future. And as always, at the end of the project, EAD will turn over to you any as-built programs, HMI/SCADA applications, and drawings that we have developed for your records.

EAD loves the challenge of fitting complex PLC migrations into tight downtime windows. We have the experience, processes, and skills to meet all your PLC Migration needs. Send us an email or give us a call at +1.402.884.8650 to speak with an Automation PLC migration expert.